Line Shackles - The Next Step Beyond Soft Shackles

From Soft Shackles to Line Shackles

In my earlier article "The History of the Soft Shackle," I traced how soft shackles evolved from simple Dyneema loops into the compact, high-strength designs most sailors use today. Nearly all of the soft shackles now sold include features I introduced years ago, yet there is an irony in that success: I rarely use them myself. The only place they ever made sense aboard my boat was on overlapping genoas, where the knot could hide neatly inside the sail's clew ring and keep the sheets from snagging when tacking. But I have since retired those sails - they are up in the attic now - so even that one remaining use has disappeared.

For almost everything else on my boat, I use what I call line shackles. They work on the same basic principle as a soft shackle but eliminate the separate piece altogether. Instead, the connection is built right into the line itself. It is faster, cleaner, and better suited to many of the places where a soft shackle feels like one part too many.

What Is a Line Shackle

A line shackle is like a soft shackle that has been divided in two.

One half is a Dyneema line with an adjustable eye splice - for example, the end of a sheet. Instead of locking the splice right at the eye, the lock stitching is placed several inches down the line. This allows the eye to open up, just like the loop of a soft shackle. A small lanyard line can be stitched in to make it easier to open the loop when you want to disconnect it.

The other half is a short loop of Dyneema finished with a diamond knot at its ends. This loop can be luggage-tagged to whatever you want to attach to - a sail's clew ring, a padeye, or the eye splice of another line. To connect the two halves, open the adjustable eye, slip it over the diamond knot, and snug it up. The result is a secure connection that works like a soft shackle but without having to handle three separate pieces at once.

This setup is particularly handy when attaching a second light sheet before tacking a drifter in light air. You can connect the new sheet quickly, make the tack, and then remove the first line once the sail is trimmed, all without the weight and clutter of extra hardware.

Why Use Line Shackles Instead of Soft Shackles

Soft shackles are great pieces of gear. They are light, strong, and easy to make. But in practice, they can also be one piece too many. They are something else to drop, misplace, or fumble with when the boat is moving around. A line shackle removes that extra step because it is already part of the system. You do not go looking for it, it is where it needs to be.

A line shackle also simplifies many tasks that are awkward with a soft shackle. You can attach a line to a clew ring, a padeye, or an eye splice in another line with two hands instead of three. There is no need to balance a loose shackle, hold a line under load, and line everything up at once. The connection happens in one motion: open the eye, slip it over the diamond knot, and snug it down.

Another advantage is that line shackles are purpose-built. Each one fits its exact job, sheet, halyard, tack line, or control line. There is no single "standard" size or configuration because every use calls for something slightly different. That makes them better suited to custom or performance rigs, where simplicity, weight, and function all matter.

And because the line shackle is spliced into the line itself, it is always there when you need it. There is no extra piece to fetch. It is the natural evolution of the soft shackle, just lighter, cleaner, and always ready to use.

Integrating Dyneema into Other Lines

The working end of a line shackle is typically not just raw Dyneema running all the way back through the winch or clutch. Dyneema is strong and light, but it is also slippery, and that makes it hard to handle where grip matters. In most applications there needs to be a way to transition from Dyneema to polyester, or to another line that is easier to hold and runs better through hardware.

One common way to do this is to start with a high-tech line such as Warp Speed, which has a Dyneema core and a polyester cover. You simply strip the cover back far enough to expose the Dyneema where you want to form the adjustable eye for the line shackle. The polyester section remains intact for handling, while the Dyneema section provides the strength and flexibility needed for the splice.

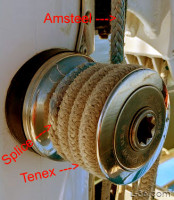

Another approach is to start with Dyneema and add a polyester cover. I use Tenex on my boat for this purpose. My jib halyard, for example, is Dyneema end to end, spliced to Tenex of a similar thickness. The splice ends up right on the winch, giving me the strength of Dyneema and the grip of polyester exactly where I need each.

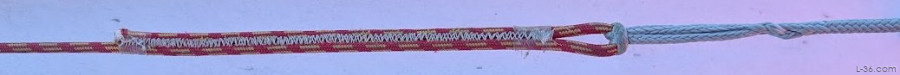

My very light air sheets are made a little differently. They are ultra-lite lines connected to a Dyneema line with an eye-to-eye luggage-tag attachment. Ultra-lite line cannot be spliced, so I double it over for about a foot and sew the two parts together with a Sailrite zig-zag sewing machine using high-strength polyester thread. I have used these sheets with my asymmetric spinnaker in 15 knots of wind, and they simply will not break. I have mostly quit using my normal spinnaker sheets, as I usually take the sail down before reaching that wind range anyway.

These examples show that there are many workable ways to integrate Dyneema with other lines. The right choice depends on the load, the handling needs, and what equipment the line passes through. Whatever the method, the goal is the same - to let Dyneema provide the strength where it counts and polyester or other fibers provide the control where you need grip.

Strength and Sizing

A line shackle is not quite as strong as a soft shackle made from the same size line because a soft shackle carries the load on two legs while a line shackle uses only one. In practice this means a line shackle has roughly half the breaking strength of an equivalent soft shackle.

On my boat most of the running rigging is 7/16 or 1/2 inch Sta-Set or equivalent, with rated strengths between about 6,600 and 8,500 pounds. Those lines are typically attached to a jib clew with a bowline, which reduces the strength to roughly 3,500 to 5,000 pounds once the knot is tied.

A soft shackle made from 3/16 inch Amsteel Blue, rated around 5,400 pounds, is actually stronger than the rope it replaces. Tests show a well-made soft shackle can reach about 175 percent of the line's rated strength. The limiting point is the diamond knot, which tests around 87 percent of line strength.

For a line shackle the adjustable eye is not the weak link, so the working section can be 3/16 inch Dyneema even when paired with 7/16 or 1/2 inch polyester lines. To maintain the full system strength, I recommend making the stopper knot from the next size larger line. That simple step offsets the single-leg load path and keeps the connection strength in the same range as the rest of the rigging.

In practical terms, if your running rigging normally sees up to 5,000 pounds of load, using a line shackle built from 3/16 inch Dyneema with a 1/4 inch stopper loop will match or exceed the working strength of a bowline in polyester line while remaining lighter and easier to handle.

Real-World Examples

Line shackles are now part of nearly every line on my boat. The control lines that run through low-friction rings use them so I can separate the Dyneema section from the polyester tail without re-reeving the entire system. My mainsail halyard uses one at the head of the sail, eliminating the metal shackle altogether, and my light-air and asymmetric spinnaker sheets both rely on them for quick changes and clean handling. The Y-sheet variation, where two sheets connect through a single Dyneema eye, is explained HERE. These few applications cover most of the load-carrying lines aboard, proving that once you start using line shackles, they tend to spread everywhere.

Why You Will Not Find These at the Chandlery

If line shackles are so great, how come you cannot find them at West Marine or Defender? The answer is simple: every one is application and boat dependent. There is not a standard size or configuration that fits all situations. Each is made for a specific purpose, and the details depend on how the boat is rigged. A boat manufacturer could certainly rig a new boat with them, but for most of us they are a DIY project.

It is the same reason you buy rope instead of pre-made sheets. The material is universal, but the way you finish it depends on your boat. Line shackles are like that. They are a technique, not a product. You make them yourself or have a rigger build them to fit a specific purpose. Once you understand how they work, you can adapt them to almost any situation on board.

Closing Thoughts

Line shackles started as an experiment, a way to simplify rigging by building the connection right into the line instead of adding another piece. Over time they have replaced nearly every soft shackle on my boat. They are strong, easy to use, and once you have them in place, they simply disappear into the rigging.

What makes them work is their simplicity. There are no moving parts, nothing to drop, and nothing to jam. They combine the strength of Dyneema with the handling qualities of polyester, tailored exactly to each job. You can build them yourself with a few basic splicing tools and some patience, and once you do, you will likely start seeing new places to use them.

I expect line shackles will remain mostly a DIY idea rather than a commercial product, but that is part of their appeal. They reward sailors who like to make their own gear and think through how things work. For me, they represent the next step in the same evolution that began with the soft shackle - simpler, lighter, and better suited to the way we actually use our boats.

NOTICE: Some pages have affiliate links to Amazon. As an Amazon Associate, I earn from qualifying purchases. Please read website Cookie, Privacy, and Disclamers by clicking HERE. To contact me click HERE. For my YouTube page click HERE